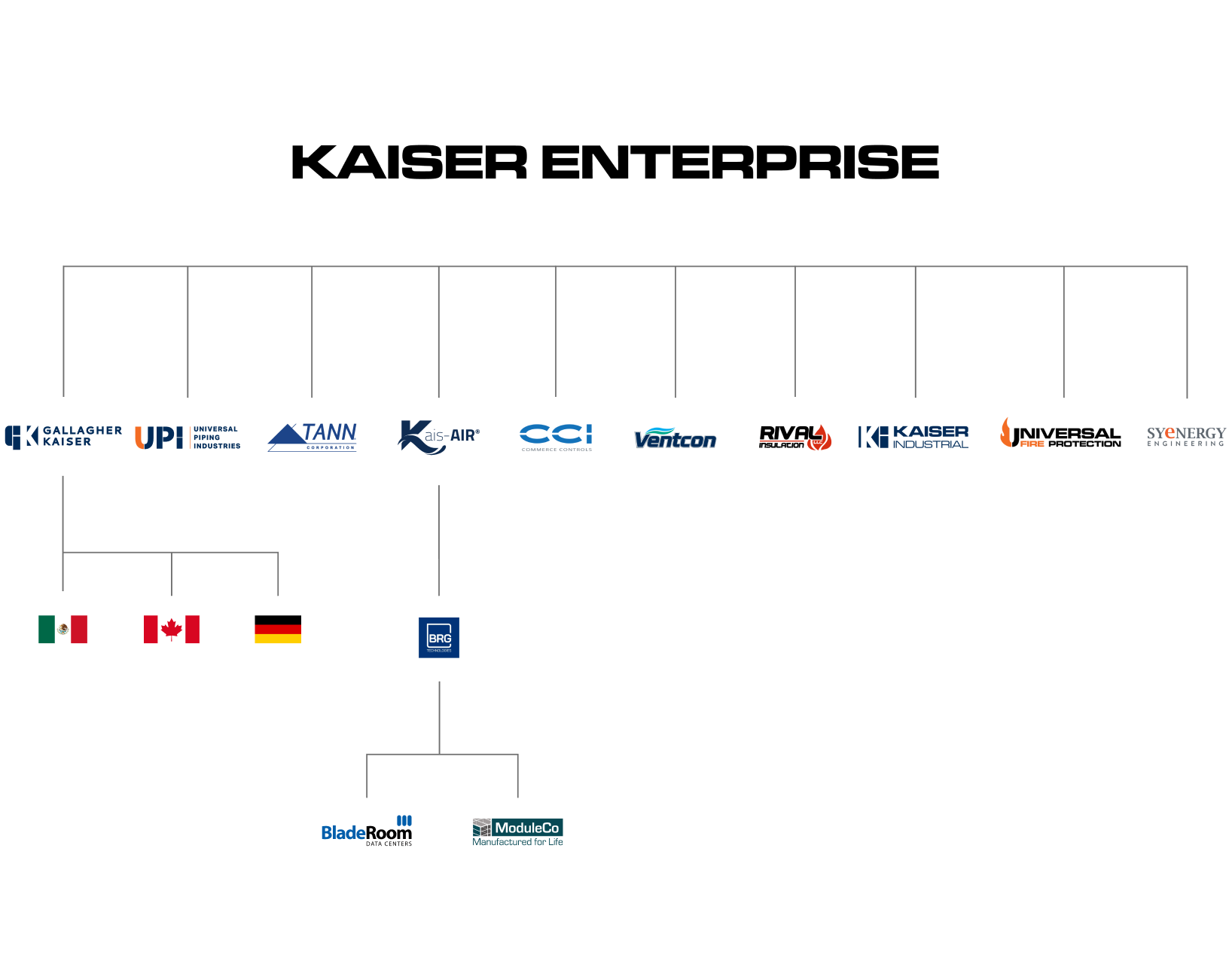

The Kaiser Enterprise is made up of multiple divisions & subsidiaries. From a turn-key paint shop, to a battery manufacturing facility, to a turn-key hyperscale data center, to a wastewater treatment facility: the Kaiser Enterprise has a wide range of capabilities. Importantly, this team has the in-house resources to design, engineer, fabricate and install.

Learn More

10

Companies

1600

Employees

1.3 Million

SQFT of Manufacturing

0

Missed Launch Dates

Item 1 of 18

WHO WE ARE

What We Do

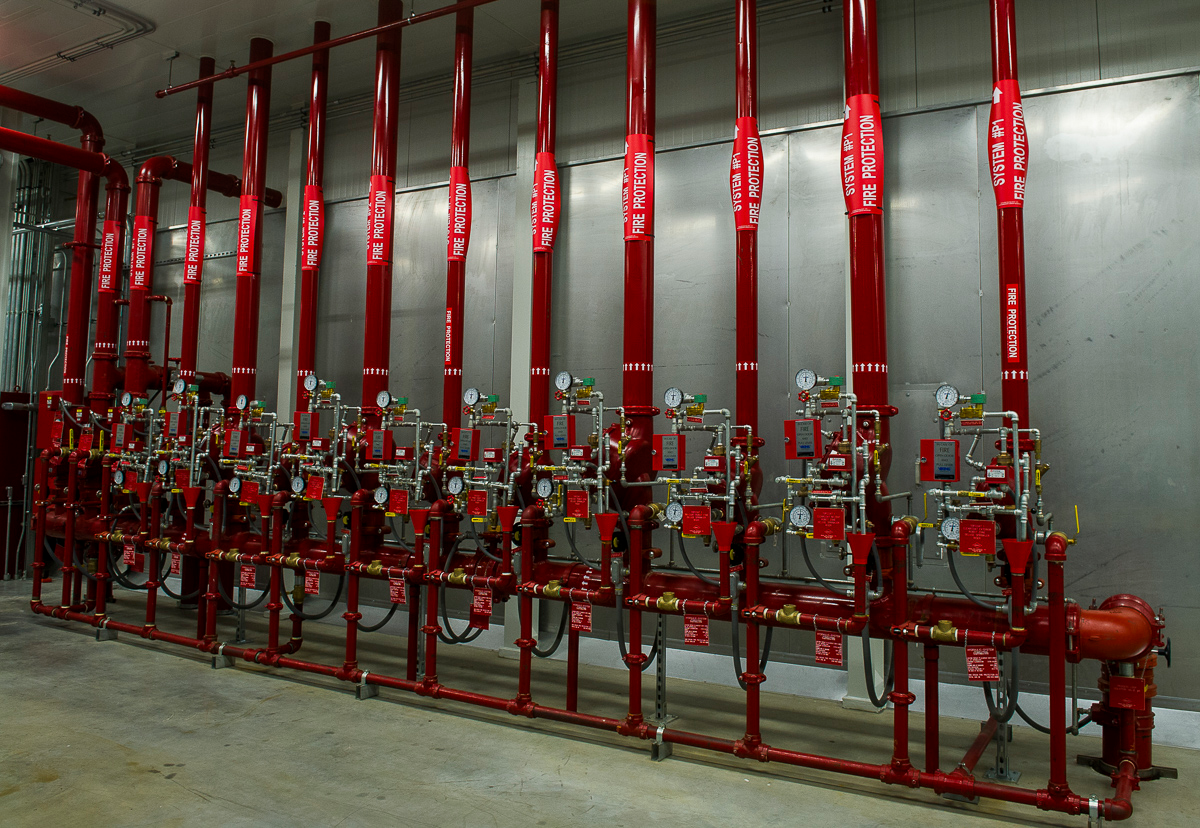

- Design & Engineering

- Fabrication

- Skilled Installation

- Procurement & Product Integration

- Construction Management

- Commissioning & Launch

- Research & Development